Features

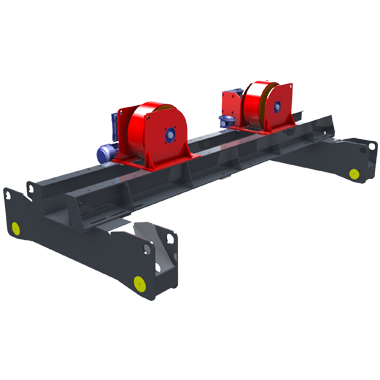

- Apak Interwelding conventional type inverters are products that offer quality and economical solutions in cases where variable diameters are not available in cylindrical welding applications.

- Converters increase speed and efficiency in automatic welding systems and manual welding, as well as reducing the workforce and increasing efficiency by reducing the use of auxiliary equipment such as cranes within the enterprise.The inverters provide the operator with precise and smooth speeds for clockwise and counter clockwise conversations.

- As Apak Interwelding, it produces converters with a capacity of 12 to 150 tons. Considering the needs of customer’s production, it produces special productions up to 250 tons.

Русский

Русский Türkçe

Türkçe