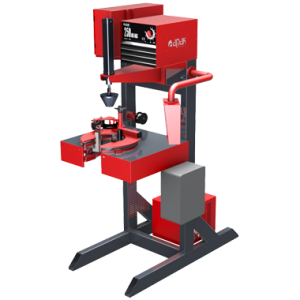

Features

- It is a system designed to be used in productions with mass production needs. It can perform continuous welding by switching

between the parts to be welded with 2 fixing jaws on the system. - It offers a visually flawless starting and ending opportunity with the ability to start welding from different points of the workpiece.

- With this system, you can continue uninterrupted production by minimizing human labor.

- The system, which can be adjusted without being dependent on the shape, has the ability to weld pipes and profiles with each form.

- Both MIG and TIG welding methods can be used on the system.

Русский

Русский Türkçe

Türkçe